In today’s rapidly evolving manufacturing landscape, innovation is the key to staying ahead of the competition. Hot Isostatic Pressing (HIP) and Additive Manufacturing (AM), commonly known as 3D printing, are among the many technologies currently growing. Both technologies have gained prominence in industries ranging from aerospace and automotive to medical and beyond, thanks to their ability to create complex and high-performance components.

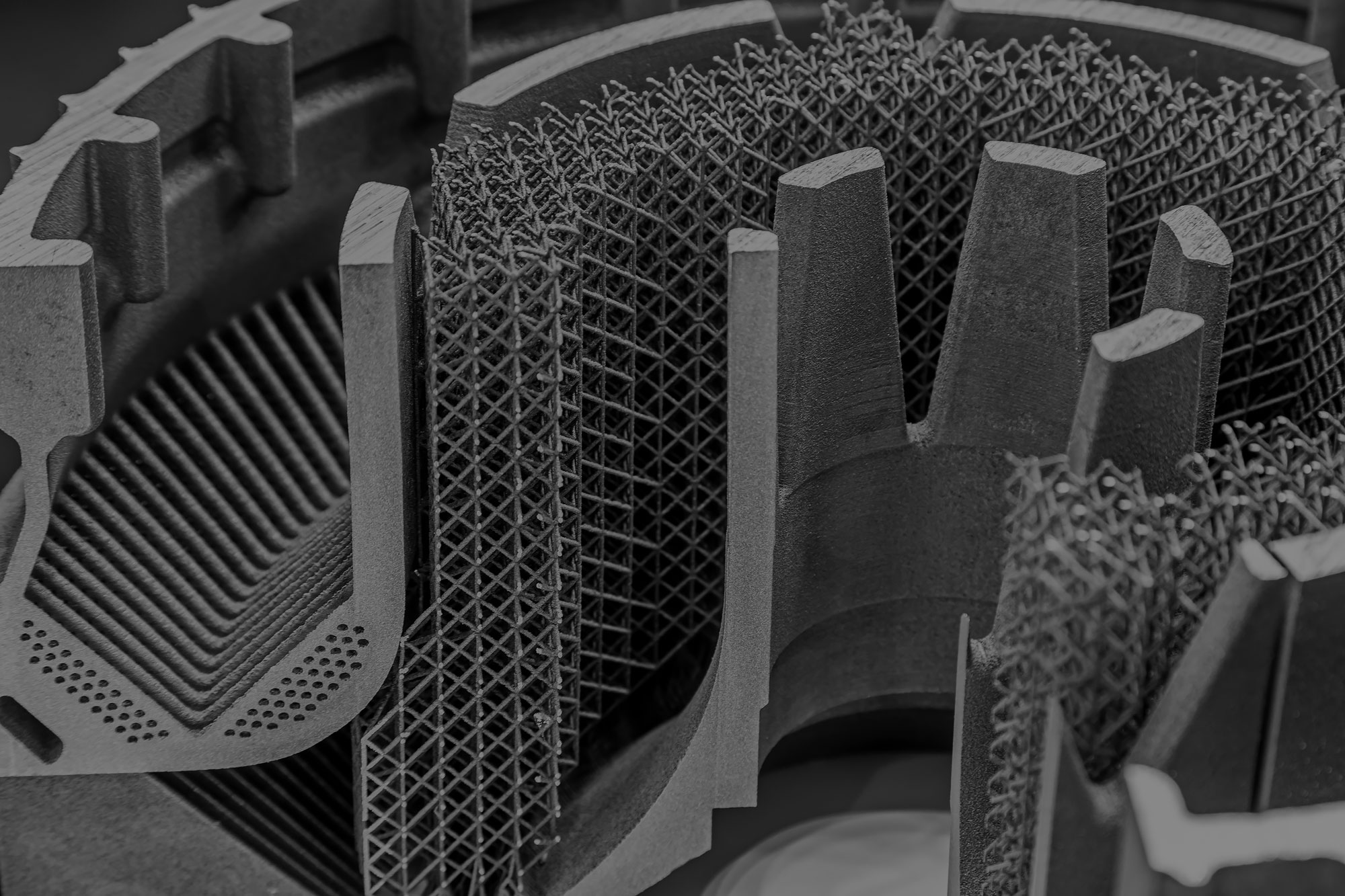

Additive Manufacturing is celebrated for its ability to create intricate and complex geometries layer by layer. It has enabled designers and engineers to push the boundaries of what’s possible in terms of component design and customization. While it offers numerous advantages in terms of design flexibility and rapid prototyping, it also presents certain challenges related to material strength and structural integrity—including the potential for porosity and inconsistencies in material properties.

This is where Hot Isostatic Pressing offers a solution:

Hot Isostatic Pressing & Additive Manufacturing

Hot Isostatic Pressing is a high-pressure, high-temperature process used to improve the density and mechanical properties of materials. It involves subjecting a component to extreme pressure and temperature within a vessel filled with inert gas. This process effectively eliminates porosity, enhances material properties, and ensures structural integrity. It’s the go-to choice for ensuring the reliability of components used in demanding industries such as aerospace and defense.

By subjecting 3D-printed components to Hot Isostatic Pressing, the materials can be further densified and strengthened, addressing the porosity issues often associated with Additive Manufacturing. This results in parts that meet the stringent quality requirements of industries like aerospace and medical, where safety and reliability are paramount.

Why Kittyhawk?

Our team at Kittyhawk specializes in Hot Isostatic Pressing. Our expertise combined with multiple units and locations makes us the go-to choice for businesses seeking to leverage the combined power of HIP and Additive Manufacturing—delivering fast turnaround times and competitive pricing but also the assurance of receiving components of the highest quality. This dedication to quality has earned Kittyhawk one of the best reputations within the industry, with more than 40 years of proven excellence.

The relationship between Hot Isostatic Pressing and Additive Manufacturing is a critical element of the continuous advancement of manufacturing technologies. Together, they offer a comprehensive solution that addresses the challenges of producing high-quality, precise components. With Kittyhawk’s expertise in Hot Isostatic Pressing, businesses can confidently enhance their Additive Manufacturing processes and stay ahead of the competition.

CONTACT US to learn more.

About Kittyhawk

Kittyhawk Inc. is a premier provider of Hot Isostatic Pressing services, established in 1981. We cater to various industries such as aerospace, defense, automotive, oil & gas, firearms, medical, and commercial, delivering quality parts with quick turnaround times. Adhering to AS9100 and NADCAP standards, we also comply with ITAR and EAR import and export regulations and hold a CLASS 07 FFL. Visit www.kittyhawkinc.com to learn more.