HOT ISOSTATIC PRESSING

MATERIAL PROCESSING SOLUTIONS

For more than 40 years, Kittyhawk has provided Hot Isostatic Pressing services to resolve metal manufacturing challenges quickly and efficiently.

3

8

HIP Vessels

70

Skilled Professionals

For more than 40 years, Kittyhawk has provided Hot Isostatic Pressing services to resolve metal manufacturing challenges quickly and efficiently.

3

Facilities

8

HIP Vessels

70

Skilled Professionals

What is Hot Isostatic Pressing (HIP)?

Hot Isostatic Pressing is an advanced material processing method that uses high heat and pressure in an inert gas environment to enhance mechanical properties.

The process eliminates voids to maximize density, forms high-strength bonds, and offers a high-tech, high-quality, and cost-effective solution for optimizing metal part production.

Leading organizations in additive manufacturing, casting, metal injection molding, near-net shape production, and sputtering trust Kittyhawk’s Hot Isostatic Pressing services to deliver superior components.

Microstructure demonstration—densification of material.

Eliminating Internal Porosity

Improving Mechanical Properties

Creating High-Strength Bonds

HIP Solutions Tailored to Your Needs

We are purposely built with the capacity to serve our growing customer base. Kittyhawk offers proven expertise, advanced technology, and tailored solutions for manufacturers:

- Versatile Vessel Sizes: Handling diameters from 18″ to 63″

- Diverse Material Expertise: Titanium, aluminum, steel, superalloys, and more

- Advanced Technology: Equipped with Quintus vessels featuring Uniform Rapid Cool (URC) capabilities

Partnering with Kittyhawk has been an asset to our operations. Their customer service, expertise, and delivery have consistently exceeded our expectations. In our highly regulated environment, their commitment to quality and consistency makes them a trusted and reliable partner we can count on.”

Nick Cordaro

President | SpiTrex Orthopedics

Kittyhawk is a well-managed organization, always delivering reliable service and responding quickly to our needs.”

Hadi Khandehroo

CEO / President | Miller Castings, Inc.

It’s been a pleasure working with Kittyhawk as a collaborative growth partner for CPP Titanium.”

Anthony Morton

Areas of Expertise

Kittyhawk provides HIP solutions for a wide range of industries and manufacturing methods:

Why Choose Kittyhawk?

Focused on delivering the highest levels of quality and customer service, our goal is to reduce time and complexity across fragmented supply chains. Working with Kittyhawk means:

- Fastest Turnaround Time in The Industry

- Proven Quality Management System

- Commitment to Innovation and Growth

- Unmatched Focus on Customer Success

- Decades of Industry Leadership

News & Updates

Stay up to date with industry insights, technological advancements, and Kittyhawk’s latest updates:

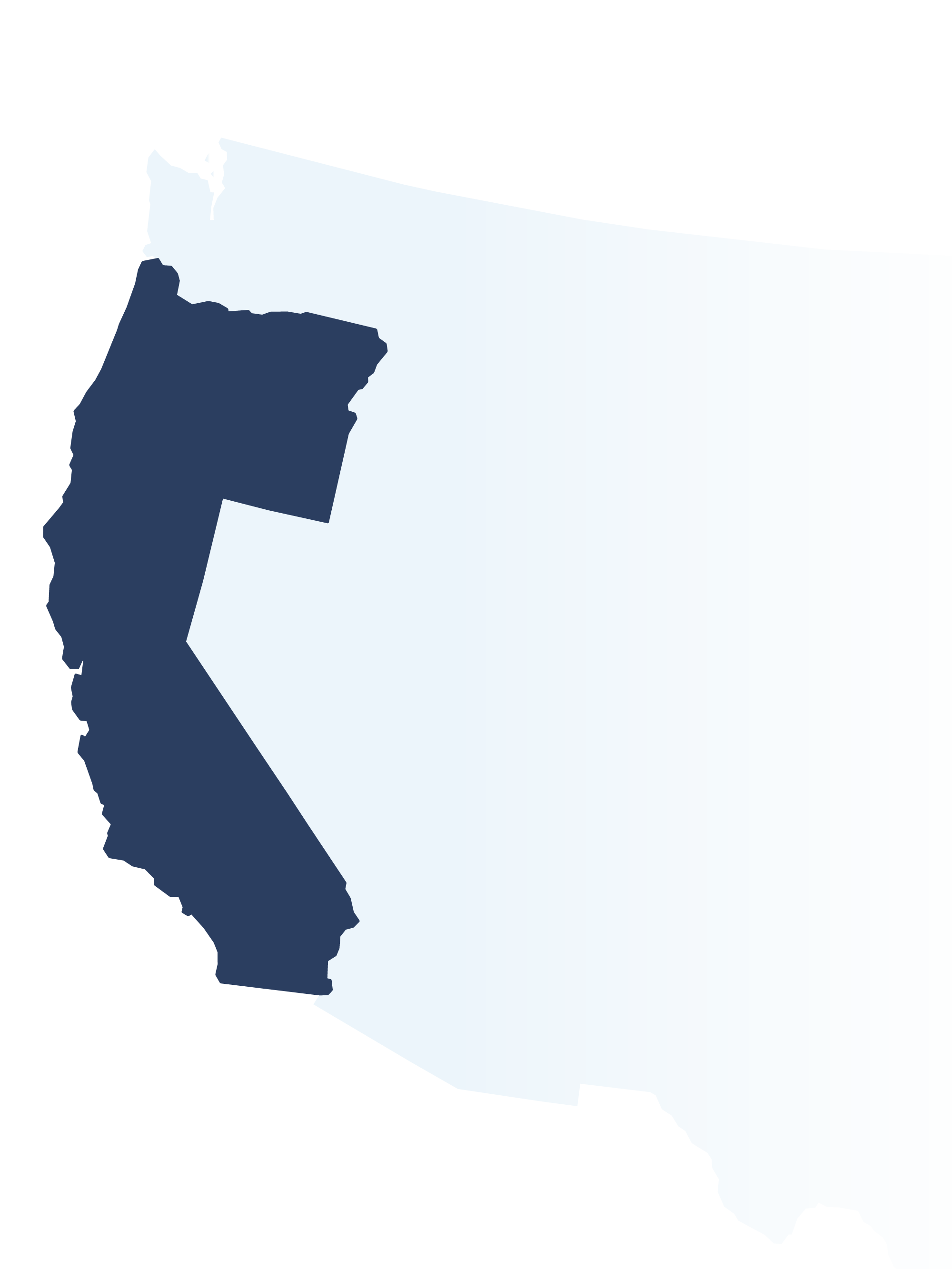

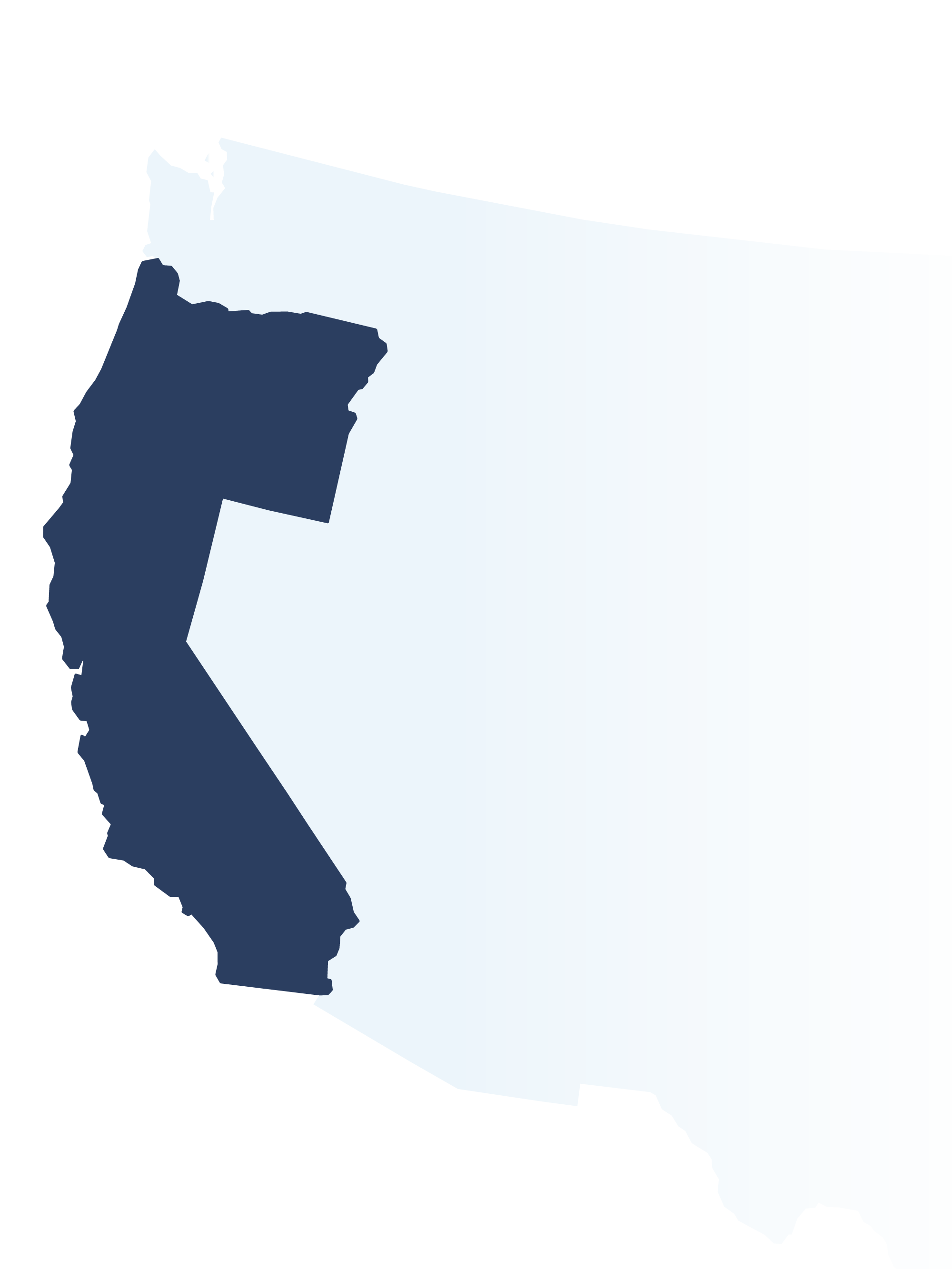

About Kittyhawk

Since 1981, Kittyhawk has been at the forefront of the Hot Isostatic Pressing industry. Our team of skilled professionals operates across three U.S. based facilities to deliver timely, economical, and high-quality HIP solutions.

Request a Quote

Request a Quote

Questions?

Give Us a Call:

714-895-5024

California

11651 Monarch Street

Garden Grove, CA 92841

Oregon

301 S Redwood Street

Canby, OR 97013

4322 Marion Street SE

Albany, OR 97322

Navigation

© 2025 Kittyhawk Inc. | Designed by MOONCRUX