Hot Isostatic Pressing is a process that involves the application of high pressure and temperature to materials in order to improve their properties. It is often used in the manufacturing of aerospace and medical components, as well as in the production of other high-performance parts. But is it a heat treatment?

The answer to this question is not a simple yes or no. While HIP does involve the application of heat, it is not considered a traditional heat treatment. Heat treatments are typically used to alter the mechanical, physical, or sometimes chemical properties of a material by heating it to a specific temperature and holding it there for a certain amount of time.

Hot Isostatic Pressing is a combination of heat and pressure. The metal components we process are heated to a high temperature while simultaneously being subjected to high pressure in an inert gas environment. This process can help to eliminate voids and other defects that may have formed during the manufacturing process.

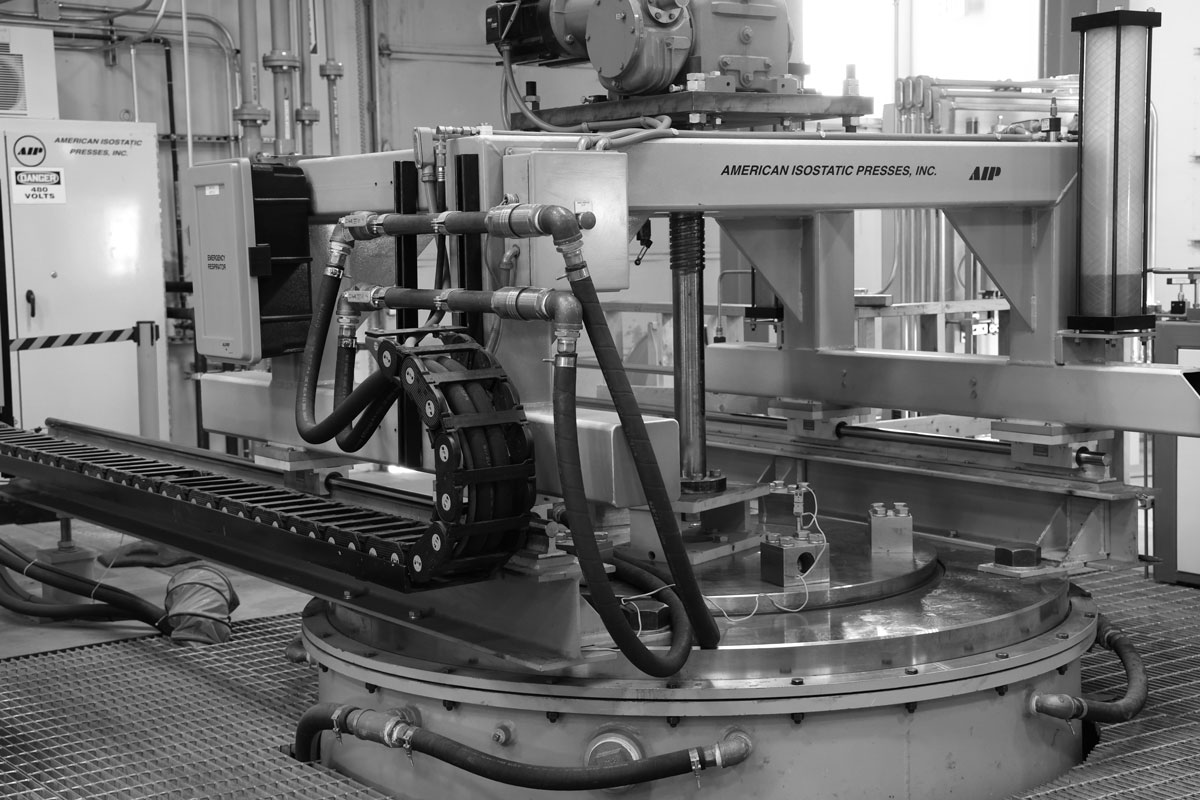

Hot Isostatic Pressing equipment at a Kittyhawk facility.

In addition to improving the material’s mechanical properties, HIP can also be used to improve its microstructure. By subjecting the material to high pressure, the atoms within it are forced closer together, which can help to eliminate any gaps or voids that may have formed. This can result in a material that is stronger, more durable, and more resistant to wear and tear.

So while HIP does involve the application of heat, it is not considered a traditional heat treatment. Instead, it is a unique process that combines the benefits of both heat and pressure to produce materials with improved properties. If you’re looking for a way to improve the performance of your components, consider incorporating Hot Isostatic Pressing by Kittyhawk into your manufacturing process.

Interested in incorporating HIP? CONTACT US ⟶

About Kittyhawk

Kittyhawk Inc. is a premier provider of Hot Isostatic Pressing services, established in 1981. We cater to various industries such as aerospace, defense, automotive, oil & gas, firearms, medical, and commercial, delivering quality parts with quick turnaround times. Adhering to AS9100 and NADCAP standards, we also comply with ITAR and EAR import and export regulations and hold a CLASS 07 FFL. Visit www.kittyhawkinc.com to learn more.